|

|

|||||||||||||||||||||||||

| Home | Company | Technologies | Equipment | Contact | |||||||||||||||||||||

|

|

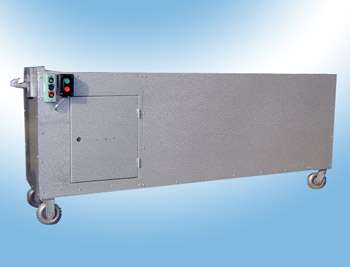

Sorting Lines This 12-man sorting system is 64' long x 42" wide 12-man picking table with twelve sorting chutes (six on each side), This standard infeed conveyor, emergency shut-offs on both sides, stairs, walkways, controls. Excellent for C&D or MSW. We can customize a sorting station of any size, including portable units. All parts are new or completely refurbished. Options available: crossbelt magnets, steel-belted conveyors, trommel screens.

|

||||||||||||||||||||||||

|

|

Trommel Screens

Widely used

in metallurgy, building material, chemical, food, chemical industries of

abrasive and granular materials sorting machine, also used to wash the

material screening items |

||||||||||||||||||||||||

|

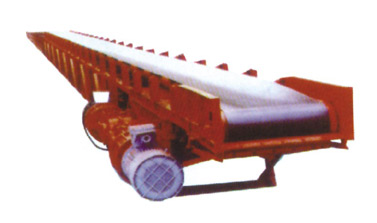

Conveyors Conveyor is a general-purpose products using cotton canvas, nylon, polyester canvas and steel cord conveyor belt components for drag cited continuous conveyor equipment, can be widely used in electric power, coal, mining, iron and steel, building materials, chemicals, tobacco , environmental protection, food, light industry, oil and many other industries. Transport various bulk, block or integer goods with loose density 500-2500kg / m³. With the features of great traffic and climbing ability, and Small noise, easy maintenance, good interchangeability of wearing parts etc, this kind of conveyor is good for the transport system automation control. And the working environment temperature is lower than 40 °C |

||||||||||||||||||||||||

|

|

Circular Vibrating Screen

Our Circular Vibrating Screen

adopts German technology, and is specially designed to sieve different

sizes of aggregate. It is also applied in coal dressing, ore dressing,

building material, electricity and chemical industries.

1. High vibrating force with

unique eccentric structure. Adopt advanced construction, making the

vibrating force powerful.

3. Simple structure, easy to

repair. |

||||||||||||||||||||||||

|

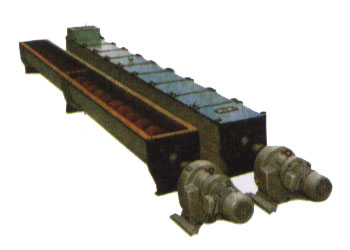

Screw Conveyors Our screw conveyors are used extensively in sugar, cement, fertilizer, chemicals, food, agro chemicals and breweries. These machines comprise of screw inside the hollow pipe, contained within tube. It is turned with the help of a motor for delivering material from one end of the conveyor to the other. Working Principle The Conveyor Screw imparts a smooth positive motion to the material as it rotates within the trough. Couplings and Shaft connect and transmit motion to the subsequent screw conveyors. Held in place by self-locking Tem-U-Lac bolts. |

||||||||||||||||||||||||

|

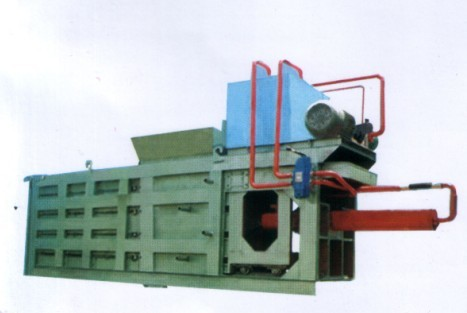

Balers This machine is used for packing all of the light and loose material, such as straw, pasture, waste paper,cotton, cloth,plastic, wool, and Recoverable Garbage and so on. It helps to reduce the volume, increase the density, it is convenient to transport and save. This machine is the good helper in multipurpose using and exploiting biomass energy.

|

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

Tire Shredding

the cutter is with high hardness, high wear, and can be repeated use and repair, so a longer service life. |

||||||||||||||||||||||||

|

|

Tire Bead Peeler Productivity:80-100 tires/hour

Motor Power:15KW

|

||||||||||||||||||||||||

|

|

Vertical compound crusher Widely used in cement, building materials and artificial sand industry, limestone, river gravel, dolomite, slag, coal stone, refractories, etc., in the hardness of stone crushing operation. Especially suitable for artificial sand and the road surface broken by stone processing. The crushing ratio, broken high moisture content, moisture content of the ideal material processing, the particle size can be adjusted, non-screen bar set, containing a large quantity of clay material will not plug into the body material can not be broken Automatic discharge will not cause equipment damage. The DC crushing equipment, high efficiency, unique structure, smooth operation, no noise, easy maintenance, you can easily open the doors of work replacement of wearing parts. |

||||||||||||||||||||||||

|

Pelletizing Lines The line is full automatic,includes hammer mill,rotary dryer,pellet mill,cooling system,screener,dust collecting system,computer-control center etc. Of course we can design most suitable flow chart according to your real situation.

|

||||||||||||||||||||||||

|

|

Packaging Machines Our Packaging products are mainly used for packing and conveying all kinds of materials such as powder, pellet in chemical industry, grain industry, feed industry, food industry, fertilizer industry, rubber industry, construction material industry, etc. And, of course, we supply not only the packing scales and conveyors, but also the whole resolutions according to your special demands. |

||||||||||||||||||||||||

|

Solar Power

Applications

Capacity : 2000VA |

||||||||||||||||||||||||

|

Atmospheric Water Generators Key Specifications/Special Features:

|

||||||||||||||||||||||||